3D Drucker, Fertigmodelle, Bausätze und Zubehör

Wanhao D10 Hot-End Set Screw

Set Screw for the Hot-End on Wanhao Duplicator 10.

Used to hold the Nozzle and Heatbreak in place in the Block.

|

|---|

Creality 3D 30-pin Extruder PCB

30-pin Extruder PCB for the CR-10S Pro, CR-10S Pro V2 and CR-10 Max.

|

|---|

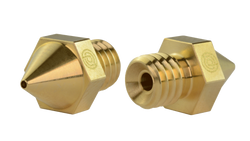

MK8 Nickel Plated Copper Nozzle 0-4 mm - 1 pcs

MK8 Nickel Plated Copper Nozzle 0,4 mm - 1 pcs

Fits to: Creality CR-10 series, MakerBot Replicator 2, CraftBot series and others.

The premium nozzles from PrimaCreator are a series of replacement nozzles that can make more difference for the result than you may think. To have a high-quality nozzle is like having a sharp pencil, you need it to get a great print.

All nozzles from PrimaCreator are made from the best high-quality brass, copper or steel (depending on type) and are completed in a state of the art factory. All nozzles are manufactured with a tolerance of less than ± 0.01 mm. This means that your filament will have a very smooth and clear surface while extruding which, of course, results in better prints.

For best results and optimal print quality, we highly recommend that you re-level your build plate after changing to a new nozzle. Note that a PrimaCreator nozzle might be compatible with your printer, but the distance between nozzle and build plate must be adjusted.

The process of making a PrimaCreator nozzle begins with a selected high-quality material. When the material reaches the factory, there is first an optical inspection made of the material that are going to be used for each batch of nozzles. Then it´s time to clamp the material, in other words, make it into a long rod. In our process this only is done once, in many other (cheaper) cases, this process must be repeated several times, often as many as 3-4 times and yet you don´t get the same results.

After this process, the material goes through an ultrasonic cleaning bath and after that it is cleaned again and protected against surface oxidation.

The nozzle will now take shape with millimeter precision, the tolerance is less than ± 0.01 mm.

The process of removing sharp edges from the nozzles is a very important step as this makes up a big part of the result. If there is to much sharp edges left on the nozzle it will make the nozzle more prone to clog. So it´s essential that the nozzle is very smooth and clean before it is used. In every batch a few nozzles are selected and cut in half to make sure that every specification is met, and that the surface is in perfect condition.

The nozzles are then checked for one last time and packed individually in a protective box – ready to be shipped to you.

The series of nozzles from PrimaCreator is the perfect choice for people who only wants the best and at a great value!

|

|---|

Wanhao Koppler D20-L25 für D5 und D6

Koppler D20_L25 für Wanhao Duplicator D5 und D6

Kaufe dir diesen Wanhao Koppler D20_L25 für deinen Wanhao Duplicator D5 und D6.

|

|---|

Wanhao Duplicator 6 - Duplicator 9 Extruder - Z-axis Stepper Motor-

Stepper Motor for Wanhao Duplicator 6, Duplicator 6 Plus and Duplicator 9.

Used on Z-axis and Extruder on Duplicator 6 and Duplicator 6 Plus.

Used on Extruder on Duplicator 9 (all versions).

42-34 mm.

|

|---|

Zortrax Z-PLA filament - 1-75mm - 800g - Silber

Biodegradable and Precise Filament

Z-PLA plastic material offers exceptional precision for 3D printing complex models. This biodegradable 3D printing filament is made of environment-friendly components. With almost no shrinkage, Z-PLA guarantees high-quality details and exceptionally smooth surfaces.

Main Features:

- High detail 3D printing

- Smooth surface

- Eco-friendly material

- Low shrinkage

Composition:

PLA (polylactic acid) - >98%

Additives and colorants – 0 ~ 2%

Applications

- High-quality parts

- Architecture mock-ups

- Detailed conceptual models

- Educational models

- Consumer goods

- Models required to be biodegradable

|

|---|

PrimaCreator Raise3D Pro2 Brass Nozzle 0-8 mm - 1 pcs

Raise3D Pro2 Brass Nozzle 0,8 mm - 1 pc

Fits to: Raise3D Pro2, Pro2 Plus and E2

The premium nozzles from PrimaCreator are a series of replacement nozzles that can make more difference for the result than you may think. To have a high-quality nozzle is like having a sharp pencil, you need it to get a great print.

All nozzles from PrimaCreator are made from the best high-quality brass or steel (depending on type) and are completed in a state of the art factory. All nozzles are manufactured with a tolerance of less than ± 0.01 mm. This means that your filament will have a very smooth and clear surface while extruding which, of course, results in better prints.

For best results and optimal print quality, we highly recommend that you re-level your build plate after changing to a new nozzle. Note that a PrimaCreator nozzle might be compatible with your printer, but the distance between nozzle and build plate must be adjusted.

The process of making a PrimaCreator nozzle begins with a selected high-quality material. When the material reaches the factory, there is first an optical inspection made of the material that are going to be used for each batch of nozzles. Then it´s time to clamp the material, in other words, make it into a long rod. In our process this only is done once, in many other (cheaper) cases, this process must be repeated several times, often as many as 3-4 times and yet you don´t get the same results.

After this process, the material goes through an ultrasonic cleaning bath and after that it is cleaned again and protected against surface oxidation.

The nozzle will now take shape with millimeter precision, the tolerance is less than ± 0.01 mm.

The process of removing sharp edges from the nozzles is a very important step as this makes up a big part of the result. If there is to much sharp edges left on the nozzle it will make the nozzle more prone to clog. So it´s essential that the nozzle is very smooth and clean before it is used. In every batch a few nozzles are selected and cut in half to make sure that every specification is met, and that the surface is in perfect condition.

The nozzles are then checked for one last time and packed individually in a protective box – ready to be shipped to you.

The series of nozzles from PrimaCreator is the perfect choice for people who only wants the best and at a great value!

Marks/dots on Nozzle = Size

- 0 = 0.20mm

- 3 = 0.40mm

- 4 = 0.60mm

- 5 = 0.80mm

|

|---|

Wanhao Spulenhalter für Filament Duplicator i3

Wanhao Spulenhalter für Filament Duplicator i3

Kaufe dir diesen Spulenhalter für Filament Wanhao Duplicator i3.

Produkteigenschaften:

- Filament-Spulenhalter-Halterung

- Passt zu Duplicator i3

|

|---|

Zortrax Nozzle Cap for M200 - M300 Plus - M300 Dual and Inventure

A set of spare teflon nozzle caps dedicated for Zortrax Inventure, M200 Plus, M300 Plus and M300 Dual 3D printer. Each set consists of four caps.

|

|---|

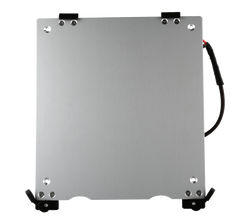

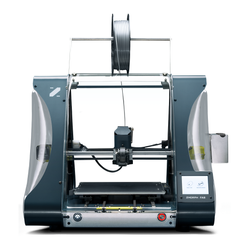

Zmorph Fab 3D Printer

Zmorph Fab 3D-Drucker

ZMORPH FAB 3D-Drucker ist das neueste Modell des Herstellers ZMorph und ist ein Drucker, wo Du alles, was Du brauchst, in einem funktionalen und schönen Design verpackt hast.Mit dem ZMORPH FAB kannst Du deinen Schreibtisch in eine Werkstatt verwandeln.

Sofort einsatzbereit:

Der FAB verfügt über eine automatische Kalibrierung und erkennt, welcher Werkzeugkopf verwendet wird. Dank dessen kannst Du den 3D-Drucker auspacken und innerhalb weniger Minuten in Betrieb nehmen.

Einzel- oder Doppelextrusion:

Beim FAB ist der Einfach-Extrusionswerkzeugkopf Standard, doch der Dual-Extrusionswerkzeugkopf ist optional ebenfalls erhältlich. Mit dem dualen Extrusionswerkzeugkopf kannst Du Multimaterialdrucke erstellen oder ihn für den Druck von Trägermaterialien, wie PVA verwenden.

Auto-Kalibrierung:

Mit der fortschrittlichen automatischen Kalibrierung der Bauplatte musst Du dir keine Sorgen mehr über fehlgeschlagene Drucke aufgrund einer schlecht nivellierten Bauplatte machen.Eine perfekt eingestellte Bauplatte ist eines der wichtigsten Dinge, um einen erfolgreichen Druck zu erstellen.

Großer Bildschirm:

Der klare und scharfe Touchscreen macht es sehr einfach, auf alle Einstellungen zuzugreifen und den Fortschritt des aktuellen Druckauftrags zu verfolgen.

Hervorragende Verarbeitungsqualität:

Hochbelastbare Aluminiumplatten sorgen für erstaunliche Steifigkeit und Stabilität. Außerdem schützt sie die Elektronik vor Staub oder Rückständen vom Drucken oder der Verwendung des CNC-Werkzeugkopfs.Die sehr robuste Konstruktion ist so ausgelegt, dass die Plattform stabil genug ist, um sowohl 3D-Druck als auch CNC-Betrieb zu bewältigen.

Saubere Luft:

Der FAB ist mit einem Kombifilter ausgestattet. Der Filter ist eine Kombination aus einem HEPA- und einem Kohlefilter. Der HEPA-Teil kümmert sich um die Entfernung von Partikeln, und die Kohlenstoffteile kümmern sich um Dämpfe und Gerüche.

Geräuschloser Betrieb:

Durch die Verwendung nur der besten Stepper-Treiber und einer stabilen Plattform ist der Drucker im Vergleich zu anderen ähnlichen Druckern sehr leise.

Inklusive Software:

Die All-in-One-Software für 3D-Druck, CNC-Fräsen und Lasergravieren und -schneiden. Alle Zmorph-Werkzeugköpfe werden unterstützt. Probiere die Materialvoreinstellungen aus oder arbeite selbst daran. Voxelizer hat einen optimierten Arbeitsablauf für Zmorph 3D-Drucker, der die besten und schnellsten Ergebnisse gewährleistet.?

SMART-Werkzeugköpfe (optional):

Der Wechsel der Arbeitsabläufe in Zmorph Fab ist dank der automatischen Werkzeugkopferkennung schnell und einfach. Das Umschalten der Werkzeuge erfordert nur wenige einfache Schritte und dauert nicht länger als eine Minute. Du kannst sofort und ohne zusätzliche Bastelei arbeiten.? Zmorph Fab verfügt über ein austauschbares Werkzeugkopfsystem. Mit zusätzlichen Werkzeugköpfen kannst Du den 3D-Drucker einfach in eine CNC-Fräsmaschine oder einen Lasergravierer und -schneider verwandeln.?

|

|---|

Kategorien

3D Prima

3D Prima Accante

Accante Anet

Anet ANTCLABS

ANTCLABS Anycubic

Anycubic Artillery 3D

Artillery 3D BCN3D

BCN3D BIQU 3D

BIQU 3D Bondtech

Bondtech Buildtak

Buildtak Creality

Creality Creatbot

Creatbot Deltaco

Deltaco Flashforge

Flashforge Formbot

Formbot Intamsys

Intamsys Kingston

Kingston Lay-Filaments

Lay-Filaments Magigoo

Magigoo Mayku

Mayku Micro Swiss

Micro Swiss Monocure3D

Monocure3D Mosaic

Mosaic Myriwell

Myriwell NinjaTek

NinjaTek ohne Angabe

ohne Angabe Phaetus

Phaetus PrimaCreator

PrimaCreator Raise3D

Raise3D Sinterit

Sinterit Snapmaker

Snapmaker Sunlu

Sunlu SUNON

SUNON Taulman

Taulman Ultimaker

Ultimaker Voxelab

Voxelab Wanhao

Wanhao XYZ Printing

XYZ Printing ZMorph

ZMorph Zortrax

Zortrax