Produkte von BCN3D aus der Kategorie Filament & Resin > Hersteller > BCN3D

BCN3D Nylon Cleaning Method Kit

Es wird empfohlen, dass Hotend regelmäßig zu reinigen, um Probleme mit Unterextrusion zu vermeiden. Andererseits ist diese Wartung beim Wechsel von Materialien unerlässlich, insbesondere wenn sich deren Drucktemperaturen unterscheiden.

Der beste Weg, die Düse sauber zu halten und die Lebensdauer des gesamten Hotends zu verlängern, ist die Befolgung der Anweisungen in diesem Video.

|

|---|

BCN3D Epsilon W27 - Sigma D25 Right Extruder Cable (FFC E1)

Right Extruder FFC (Flexible Flat Cable) for BCN3D Epsilon W27 and Sigma D25.

|

|---|

BCN3D Epsilon W27 - Sigma D25 Left Extruder Cable (FFC E0)

Left Extruder FFC (Flexible Flat Cable) for BCN3D Epsilon W27 and Sigma D25.

|

|---|

BCN3D Epsilon W27 - Sigma D25 Right X-axis Cable (FFC X1)

Right X-axis FFC (Flexible Flat Cable) for BCN3D Epsilon W27 and Sigma D25.

|

|---|

BCN3D Epsilon W27 - Sigma D25 Left X-axis Cable (FFC X0)

Left X-axis FFC (Flexible Flat Cable) for BCN3D Epsilon W27 and Sigma D25.

|

|---|

BCN3D Filaments ABS - 2-85 mm - 2-5 kg - Black

Overview

ABS (acrylonitrile butadiene styrene) is one of the most common technical materials in several industries around the globe. Its an engineering material which combines rigidity and resistance to impacts. It is the ideal material for technical applications and moving parts.

Traditionally a challenging material to print with FFF printers, it has been re-formulated to ensure good interlayer adhesion and to reduce warping. Our grade allows for excellent dimensional accuracy and high durability.

Compatibility: Find out the BCN3D printers and filaments compatibility

Applications

- Parts under high mechanical stress

- Strong prototypes and end-use parts

- Aesthetic models

- Commonly used on electronic or appliances cases, suitcases and phones

- Precision fits, knobs, lids and buttons

- Rigid models with snap-fit joints

Properties

- Attractive matt surface quality

- Good stiffness and dimensional stability

- High impact resistance, even at low temperature (-10 ºC)

- Good heat resistance, up to 100 ºC

- Improved printability

- Water resistant

- Low resistance to organic solvents

Technical information

High temperature material that can take a hit

ABS is able to withstand high service temperature. Moreover, its excellent impact strength makes it ideal for those applications where vibrations or blows would fracture materials such as PLA or PET-G.

High thermal and mechanical resistance

ABS is perfect for creating parts that are very mechanically resistant, with high thermal resistance properties, as well.

Highly-functional and mechanically strong parts

ABS is ideal for parts under high mechanical stress with and attractive matt finish.

Validate prototypes

Its great mechanical and thermal behavior make ABS the ideal material for testing prototypes before entering full production.

|

|---|

BCN3D Filaments ABS - 2-85 mm - 2-5 kg - Natural

Overview

ABS (acrylonitrile butadiene styrene) is one of the most common technical materials in several industries around the globe. Its an engineering material which combines rigidity and resistance to impacts. It is the ideal material for technical applications and moving parts.

Traditionally a challenging material to print with FFF printers, it has been re-formulated to ensure good interlayer adhesion and to reduce warping. Our grade allows for excellent dimensional accuracy and high durability.

Compatibility: Find out the BCN3D printers and filaments compatibility

Applications

- Parts under high mechanical stress

- Strong prototypes and end-use parts

- Aesthetic models

- Commonly used on electronic or appliances cases, suitcases and phones

- Precision fits, knobs, lids and buttons

- Rigid models with snap-fit joints

Properties

- Attractive matt surface quality

- Good stiffness and dimensional stability

- High impact resistance, even at low temperature (-10 ºC)

- Good heat resistance, up to 100 ºC

- Improved printability

- Water resistant

- Low resistance to organic solvents

Technical information

High temperature material that can take a hit

ABS is able to withstand high service temperature. Moreover, its excellent impact strength makes it ideal for those applications where vibrations or blows would fracture materials such as PLA or PET-G.

High thermal and mechanical resistance

ABS is perfect for creating parts that are very mechanically resistant, with high thermal resistance properties, as well.

Highly-functional and mechanically strong parts

ABS is ideal for parts under high mechanical stress with and attractive matt finish.

Validate prototypes

Its great mechanical and thermal behavior make ABS the ideal material for testing prototypes before entering full production.

|

|---|

BCN3D Filaments BVOH - 2-85 mm - 500 g

Overview

BVOH (Butenediol vinyl alcohol copolymer) is a water-soluble thermoplastic optimized for the FFF manufacturing process. Our BVOH extends the compatibility with most of BCN3D filaments and can be easily printed to create the support and then dissolved with ordinary water. In comparison with PVA, BVOH supports allow to achieve better surface quality, to orientate the part to get better mechanical properties and even to print multi-component models and mechanisms with a fastest dissolution and easier to remove.

Compatibility: Find out the BCN3D printers and filaments compatibility

Applications

- Water-soluble supports for partially enclosed cavities and complex geometries

- Smooth finish on functional prototypes

- Sacrificial molds

- Movable mechanisms

- Hollow parts

Properties

- Water-soluble material

- Compatible with PLA, Tough PLA, PET-G, TPU 98A, ABS, PA and PAHT CF15

- Fastest dissolution

- Easy to remove inside small parts

- Less clogging issues

- Highly hygroscopic

Technical information

Dissolution time BVOH vs PVA

BVOH is an outstanding support material for dual extrusion with record dissolution times in water compared with PVA. During the solubility test, BVOH shows dissolution times in water two times faster than PVA.

Wide compatibility with BCN3D Filaments portfolio

BVOH is compatible with most of the BCN3D Filaments and can be easily printed to create the support and then dissolved with ordinary water.

Printing of large overhangs

Our BVOH is compatible with PLA, PET-G, ABS, TPU, PA and PAHT CF15, thus allowing the creation of water-soluble support structures for the printing of parts also when using highly technical materials.

Printing of complex parts

Exceptional quality of the surfaces in contact with the supports and easy removal of the support even in hard-to-reach geometries.

Support for technical materials

Excellent compatibility and adhesion with ABS and exceptional quality of the surface in contact with the support material.

|

|---|

BCN3D Filaments Tough PLA - 2-85 mm - 750 g - Red

Overview

Tough PLA (Polylactic Acid) is engineered for its high impact resistance and strength, similar to those of ABS, in combination with the stiffness of PLA. This material shows excellent results in layer adhesion and is the perfect match for tooling or manufacturing aids where a high impact is needed. Tough PLA is an easy to print material with a very good surface quality.

Compatibility: Find out the BCN3D printers and filaments compatibility

Applications

- High impact and stiffness

- Easy to print

- Excellent surface quality

- Alternative to ABS

Properties

- Attractive matt surface quality

- Good stiffness and dimensional stability

- High impact resistance, even at low temperature (-10 ºC)

- Good heat resistance, up to 100 ºC

- Improved printability

- Water resistant

- Low resistance to organic solvents

Technical information

Ideal for manufacturing stiff parts

Tough PLA is 50% stiffer than ABS, and has the right balance of toughness and stiffness.

Post-processing tooling

Tooling designed to make holes at 120º of separation in injected parts. After manufacturing the parts without the holes in order to simplify the molds and save costs, this tooling allows for easier post-processing of the final part.

Customized tooling

Large-size tooling customized to fit a specific large aluminum profile. The tooling adapts to the machinery and fixes the metalic profile for more convenient post-processing.

Positioning tooling

Tooling used in the BCN3D production line to ensure the correct positioning of the LEDs during the assembly process. The color is used as a visual code to determine whether it is for one product or another.

Post-processing tooling

Tooling designed to make holes at 120º of separation in injected parts. After manufacturing the parts without the holes in order to simplify the molds and save costs, this tooling allows for easier post-processing of the final part.

Positioning tooling

Tooling used in the BCN3D production line to ensure the correct positioning of the LEDs during the assembly process.

Positioning tooling

Tooling used on the BCN3D production line to ensure correct positioning of the tacks to hold the flat cables.

|

|---|

BCN3D Filaments Tough PLA - 2-85 mm - 750 g - Blue

Overview

Tough PLA (Polylactic Acid) is engineered for its high impact resistance and strength, similar to those of ABS, in combination with the stiffness of PLA. This material shows excellent results in layer adhesion and is the perfect match for tooling or manufacturing aids where a high impact is needed. Tough PLA is an easy to print material with a very good surface quality.

Compatibility: Find out the BCN3D printers and filaments compatibility

Applications

- High impact and stiffness

- Easy to print

- Excellent surface quality

- Alternative to ABS

Properties

- Attractive matt surface quality

- Good stiffness and dimensional stability

- High impact resistance, even at low temperature (-10 ºC)

- Good heat resistance, up to 100 ºC

- Improved printability

- Water resistant

- Low resistance to organic solvents

Technical information

Ideal for manufacturing stiff parts

Tough PLA is 50% stiffer than ABS, and has the right balance of toughness and stiffness.

Post-processing tooling

Tooling designed to make holes at 120º of separation in injected parts. After manufacturing the parts without the holes in order to simplify the molds and save costs, this tooling allows for easier post-processing of the final part.

Customized tooling

Large-size tooling customized to fit a specific large aluminum profile. The tooling adapts to the machinery and fixes the metalic profile for more convenient post-processing.

Positioning tooling

Tooling used in the BCN3D production line to ensure the correct positioning of the LEDs during the assembly process. The color is used as a visual code to determine whether it is for one product or another.

Post-processing tooling

Tooling designed to make holes at 120º of separation in injected parts. After manufacturing the parts without the holes in order to simplify the molds and save costs, this tooling allows for easier post-processing of the final part.

Positioning tooling

Tooling used in the BCN3D production line to ensure the correct positioning of the LEDs during the assembly process.

Positioning tooling

Tooling used on the BCN3D production line to ensure correct positioning of the tacks to hold the flat cables.

|

|---|

BCN3D Filaments Tough PLA - 2-85 mm - 750 g - White

Overview

Tough PLA (Polylactic Acid) is engineered for its high impact resistance and strength, similar to those of ABS, in combination with the stiffness of PLA. This material shows excellent results in layer adhesion and is the perfect match for tooling or manufacturing aids where a high impact is needed. Tough PLA is an easy to print material with a very good surface quality.

Compatibility: Find out the BCN3D printers and filaments compatibility

Applications

- High impact and stiffness

- Easy to print

- Excellent surface quality

- Alternative to ABS

Properties

- Attractive matt surface quality

- Good stiffness and dimensional stability

- High impact resistance, even at low temperature (-10 ºC)

- Good heat resistance, up to 100 ºC

- Improved printability

- Water resistant

- Low resistance to organic solvents

Technical information

Ideal for manufacturing stiff parts

Tough PLA is 50% stiffer than ABS, and has the right balance of toughness and stiffness.

Post-processing tooling

Tooling designed to make holes at 120º of separation in injected parts. After manufacturing the parts without the holes in order to simplify the molds and save costs, this tooling allows for easier post-processing of the final part.

Customized tooling

Large-size tooling customized to fit a specific large aluminum profile. The tooling adapts to the machinery and fixes the metalic profile for more convenient post-processing.

Positioning tooling

Tooling used in the BCN3D production line to ensure the correct positioning of the LEDs during the assembly process. The color is used as a visual code to determine whether it is for one product or another.

Post-processing tooling

Tooling designed to make holes at 120º of separation in injected parts. After manufacturing the parts without the holes in order to simplify the molds and save costs, this tooling allows for easier post-processing of the final part.

Positioning tooling

Tooling used in the BCN3D production line to ensure the correct positioning of the LEDs during the assembly process.

Positioning tooling

Tooling used on the BCN3D production line to ensure correct positioning of the tacks to hold the flat cables.

|

|---|

BCN3D Filaments Tough PLA - 2-85 mm - 750 g - Black

Overview

Tough PLA (Polylactic Acid) is engineered for its high impact resistance and strength, similar to those of ABS, in combination with the stiffness of PLA. This material shows excellent results in layer adhesion and is the perfect match for tooling or manufacturing aids where a high impact is needed. Tough PLA is an easy to print material with a very good surface quality.

Compatibility: Find out the BCN3D printers and filaments compatibility

Applications

- High impact and stiffness

- Easy to print

- Excellent surface quality

- Alternative to ABS

Properties

- Attractive matt surface quality

- Good stiffness and dimensional stability

- High impact resistance, even at low temperature (-10 ºC)

- Good heat resistance, up to 100 ºC

- Improved printability

- Water resistant

- Low resistance to organic solvents

Technical information

Ideal for manufacturing stiff parts

Tough PLA is 50% stiffer than ABS, and has the right balance of toughness and stiffness.

Post-processing tooling

Tooling designed to make holes at 120º of separation in injected parts. After manufacturing the parts without the holes in order to simplify the molds and save costs, this tooling allows for easier post-processing of the final part.

Customized tooling

Large-size tooling customized to fit a specific large aluminum profile. The tooling adapts to the machinery and fixes the metalic profile for more convenient post-processing.

Positioning tooling

Tooling used in the BCN3D production line to ensure the correct positioning of the LEDs during the assembly process. The color is used as a visual code to determine whether it is for one product or another.

Post-processing tooling

Tooling designed to make holes at 120º of separation in injected parts. After manufacturing the parts without the holes in order to simplify the molds and save costs, this tooling allows for easier post-processing of the final part.

Positioning tooling

Tooling used in the BCN3D production line to ensure the correct positioning of the LEDs during the assembly process.

Positioning tooling

Tooling used on the BCN3D production line to ensure correct positioning of the tacks to hold the flat cables.

|

|---|

BCN3D Filaments PET-G - 2-85 mm - 750 g - Black

Overview

PET-G (Polyethylene terephthalate glycol-modified) is a polyester thermoplastic characterised by a good balance of tensile strength and elongation at break. Its high resistance to water and chemicals makes it the material of choice for water-tight containers and protective cases.

PET-G is a versatile technical material, as easy to print as PLA, but with an improved balance of mechanical, chemical and thermal properties.

Compatibility: Find out the BCN3D printers and filaments compatibility

Applications

- Parts in contact with salts, acids and alkalis

- Functional prototypes and mechanical parts

- Waterproof applications

- Structural parts subject to mild stress

- Snap-fit joints

- Commonly used in beverage bottles

Properties

- Resistance to corrosive chemicals

- Good balance of strength, impact resistance and elongation at break

- Great dimensional stability and toughness

- Good glossy surface quality

- Good abrasion resistance

- Water and moisture barrier

- Withstand operating temperatures up to 70°C

- Low rate of ultrafine particles (UFP) and volatile organic compounds (VOC)

- Compatible with PVA supports

Technical information

Good balance of strength and ductility

PET-G parts are as strong as those made with PLA but offer a better mechanical profile. PET-G is not brittle, which means that it will not snap abruptly if pulled or bended, on the contrary, it will progressively bend and stretch until reaching it maximum elongation limit of 23%.

Resistant to chemicals and humidity

PET-G is highly resistant to chemicals and humidity, which allows for disinfection and cleaning without losing its mechanical properties to hydroalcoholic solutions.

Fast Tooling

Use it to fast-track the manufacture of jigs and fixtures for your production chain.

Mechanical parts

PET-G is ideal for end-use parts demanding mechanical and thermal properties.

|

|---|

BCN3D Filaments PET-G - 2-85 mm - 750 g - White

Overview

PET-G (Polyethylene terephthalate glycol-modified) is a polyester thermoplastic characterised by a good balance of tensile strength and elongation at break. Its high resistance to water and chemicals makes it the material of choice for water-tight containers and protective cases.

PET-G is a versatile technical material, as easy to print as PLA, but with an improved balance of mechanical, chemical and thermal properties.

Compatibility: Find out the BCN3D printers and filaments compatibility

Applications

- Parts in contact with salts, acids and alkalis

- Functional prototypes and mechanical parts

- Waterproof applications

- Structural parts subject to mild stress

- Snap-fit joints

- Commonly used in beverage bottles

Properties

- Resistance to corrosive chemicals

- Good balance of strength, impact resistance and elongation at break

- Great dimensional stability and toughness

- Good glossy surface quality

- Good abrasion resistance

- Water and moisture barrier

- Withstand operating temperatures up to 70°C

- Low rate of ultrafine particles (UFP) and volatile organic compounds (VOC)

- Compatible with PVA supports

Technical information

Good balance of strength and ductility

PET-G parts are as strong as those made with PLA but offer a better mechanical profile. PET-G is not brittle, which means that it will not snap abruptly if pulled or bended, on the contrary, it will progressively bend and stretch until reaching it maximum elongation limit of 23%.

Resistant to chemicals and humidity

PET-G is highly resistant to chemicals and humidity, which allows for disinfection and cleaning without losing its mechanical properties to hydroalcoholic solutions.

Fast Tooling

Use it to fast-track the manufacture of jigs and fixtures for your production chain.

Mechanical parts

PET-G is ideal for end-use parts demanding mechanical and thermal properties.

|

|---|

BCN3D Filaments TPU - 2-85 mm - 750 g - Black

Overview

TPU (Thermoplastic polyurethane) is an elastomeric copolymer, made up of alternating soft and hard blocks, which give hardness and flexibility at the same time. This material is ideal for those applications where flexibility and durability are highly desired.

With Shore-A hardness of 98, TPU is a resistant material for several industrial applications, both mechanical or chemical. Moreover, it’s been especially designed to improve the 3D printing experience.

Compatibility: Find out the BCN3D printers and filaments compatibility

Applications

- Industrial seals, gaskets, sleeves or hinges

- Soft-touch multi-material models or handles

- Flexible-joined multi-material models

- Protective cases Shoe soles, non-slip surfaces

- Springs, seals and shock absorbers

- Wheels and rollers

Properties

- Great flexibility, rubbery behaviour

- High resistance to abrasion, wear and tear

- Great resistance to oils and chemicals

- Excellent impact resistance

- Maximum elongation of 450%

- Withstand operating temperatures up to 60°C

- Compatible with PVA supports

Technical information

Flexible with good wear resistance ideal for shock absorption

TPU is a thermoplastic elastomer, able to be extended up to 4.5 times its original size before breaking. Its exceptional elongation at break and strength make this material superior to most filaments.

Good corrosion and wear resistance

Its high oil and wear resistance and outstanding elongation at break make TPU ideal for testing functional and flexible prototypes.

Flexible prototype validation

TPU makes manufacturing soft and functional prototypes possible to validate the comfort and the flexibility of the product.

Flexible end-use application

TPU is ideal for pipe connections or rigid systems as it absorbs vibrations, expansions and contractions to protect the components from the efforts derived from the operation of the equipment.

|

|---|

BCN3D Filaments TPU - 2-85 mm - 750 g - White

Overview

TPU (Thermoplastic polyurethane) is an elastomeric copolymer, made up of alternating soft and hard blocks, which give hardness and flexibility at the same time. This material is ideal for those applications where flexibility and durability are highly desired.

With Shore-A hardness of 98, TPU is a resistant material for several industrial applications, both mechanical or chemical. Moreover, it’s been especially designed to improve the 3D printing experience.

Compatibility: Find out the BCN3D printers and filaments compatibility

Applications

- Industrial seals, gaskets, sleeves or hinges

- Soft-touch multi-material models or handles

- Flexible-joined multi-material models

- Protective cases Shoe soles, non-slip surfaces

- Springs, seals and shock absorbers

- Wheels and rollers

Properties

- Great flexibility, rubbery behaviour

- High resistance to abrasion, wear and tear

- Great resistance to oils and chemicals

- Excellent impact resistance

- Maximum elongation of 450%

- Withstand operating temperatures up to 60°C

- Compatible with PVA supports

Technical information

Flexible with good wear resistance ideal for shock absorption

TPU is a thermoplastic elastomer, able to be extended up to 4.5 times its original size before breaking. Its exceptional elongation at break and strength make this material superior to most filaments.

Good corrosion and wear resistance

Its high oil and wear resistance and outstanding elongation at break make TPU ideal for testing functional and flexible prototypes.

Flexible prototype validation

TPU makes manufacturing soft and functional prototypes possible to validate the comfort and the flexibility of the product.

Flexible end-use application

TPU is ideal for pipe connections or rigid systems as it absorbs vibrations, expansions and contractions to protect the components from the efforts derived from the operation of the equipment.

|

|---|

BCN3D Filaments ABS - 2-85 mm - 750 g - Black

Overview

ABS (acrylonitrile butadiene styrene) is one of the most common technical materials in several industries around the globe. Its an engineering material which combines rigidity and resistance to impacts. It is the ideal material for technical applications and moving parts.

Traditionally a challenging material to print with FFF printers, it has been re-formulated to ensure good interlayer adhesion and to reduce warping. Our grade allows for excellent dimensional accuracy and high durability.

Compatibility: Find out the BCN3D printers and filaments compatibility

Applications

- Parts under high mechanical stress

- Strong prototypes and end-use parts

- Aesthetic models

- Commonly used on electronic or appliances cases, suitcases and phones

- Precision fits, knobs, lids and buttons

- Rigid models with snap-fit joints

Properties

- Attractive matt surface quality

- Good stiffness and dimensional stability

- High impact resistance, even at low temperature (-10 ºC)

- Good heat resistance, up to 100 ºC

- Improved printability

- Water resistant

- Low resistance to organic solvents

Technical information

High temperature material that can take a hit

ABS is able to withstand high service temperature. Moreover, its excellent impact strength makes it ideal for those applications where vibrations or blows would fracture materials such as PLA or PET-G.

High thermal and mechanical resistance

ABS is perfect for creating parts that are very mechanically resistant, with high thermal resistance properties, as well.

Highly-functional and mechanically strong parts

ABS is ideal for parts under high mechanical stress with and attractive matt finish.

Validate prototypes

Its great mechanical and thermal behavior make ABS the ideal material for testing prototypes before entering full production.

|

|---|

BCN3D Filaments ABS - 2-85 mm - 750 g - Natural

Overview

ABS (acrylonitrile butadiene styrene) is one of the most common technical materials in several industries around the globe. Its an engineering material which combines rigidity and resistance to impacts. It is the ideal material for technical applications and moving parts.

Traditionally a challenging material to print with FFF printers, it has been re-formulated to ensure good interlayer adhesion and to reduce warping. Our grade allows for excellent dimensional accuracy and high durability.

Compatibility: Find out the BCN3D printers and filaments compatibility

Applications

- Parts under high mechanical stress

- Strong prototypes and end-use parts

- Aesthetic models

- Commonly used on electronic or appliances cases, suitcases and phones

- Precision fits, knobs, lids and buttons

- Rigid models with snap-fit joints

Properties

- Attractive matt surface quality

- Good stiffness and dimensional stability

- High impact resistance, even at low temperature (-10 ºC)

- Good heat resistance, up to 100 ºC

- Improved printability

- Water resistant

- Low resistance to organic solvents

Technical information

High temperature material that can take a hit

ABS is able to withstand high service temperature. Moreover, its excellent impact strength makes it ideal for those applications where vibrations or blows would fracture materials such as PLA or PET-G.

High thermal and mechanical resistance

ABS is perfect for creating parts that are very mechanically resistant, with high thermal resistance properties, as well.

Highly-functional and mechanically strong parts

ABS is ideal for parts under high mechanical stress with and attractive matt finish.

Validate prototypes

Its great mechanical and thermal behavior make ABS the ideal material for testing prototypes before entering full production.

|

|---|

BCN3D Filaments PVA - 2-85 mm - 500 g

Overview

PVA (Polyvinyl alcohol) is a water-soluble thermoplastic, widely adopted as a support material for FFF 3D printers. Optimized for the FFF manufacturing process, our PVA is compatible with most of BCN3D filaments and can be easily printed to create the support and then dissolved with ordinary water.

PVA supports allow to achieve better surface quality, to orientate the part to get better mechanical properties and even to print multi-component models and mechanisms.

Compatibility: Find out the BCN3D printers and filaments compatibility

Applications

- Improved thermal stability to avoid jamming and degradation issues

- Dissolves easily with ordinary water

- Compatible with most 3D printing filaments

- Better printability

- Moisture sensitive

- Biodegradable

Properties

- Detailed and glossy surface quality

- Good tensile strength

- Rigid, fragile behaviour

- Good UV resistance

- Withstand operating temperatures up to 50°C

- Odor-free, ideal for educational and office environments

- Compatible with PVA supports

- Low solvent and water resistance

Print complex parts

Exceptional surface quality in-contact with the support and easy removal of the support in difficult-to-reach geometries.

Print large overhangs

Our PVA has been specifically formulated for working as a support material for PLA, PA, TPU and PET-G so now you are able to print mechanical parts with support structures.

Orient parts to get better properties

When printing with PVA, you are able to orient your model in any possible way to customize its strength or your aesthetic requirements.

|

|---|

BCN3D Epsilon - Sigma D25 Upper Bowden Tube

Compatible with Epsilon W50, Epsilon W27 and Sigma D25.

The teflon tube (bowden) connects the extruder of the printer with the hotend.

It measures 710mm in length.

|

|---|

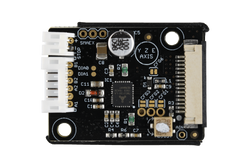

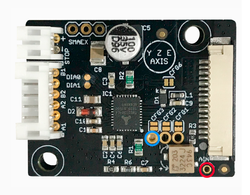

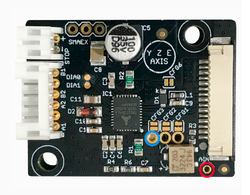

BCN3D Stepper Driver Board

Stepper Driver for BCN3D Printers.

Used for Y, Z and E axis on BCN3D Sigma R19 and Sigmax R19, and for the X, Y and Z axis on the Epsilon W27, W50 and Sigmax D25.

|

|---|

BCN3D Sigma - Sigmax X-axis Stepper Driver Board

Stepper Driver for the X-axis on BCN3D Sigma R19 and Sigmax R19.

|

|---|

BCN3D Stepper Driver Board

Stepper Driver for BCN3D Printers.

Used for Y, Z and E axis on BCN3D Sigma R19 and Sigmax R19, and for the X, Y and Z axis on the Epsilon W27, W50 and Sigmax D25.

|

|---|

BCN3D Extruder Board

|

|---|

BCN3D Lubrication Kit

Our Lubrication Kit contains all the necessary products to ease periodic lubrication operations. These operations are done to reduce friction and wear between printer mechanisms. Correct lubrication of the moving parts is critical, because it can directly affect the final quality of the prints.

The Kit includes 3 products with different functions: Grease to smear into the Z-axis leadscrew, Solvent to clean the dust and filament remnant that may fall in the guide rails and, finally, Lubrication Oil to lubricate X-axis and Y-axis.

Compatibility: All BCN3D Printers.

How to use it?

Find how to do the lubrication processes in our Support website. This maintenance is recommended through the LCD screen by the printer itself when the hotends have travelled a certain distance.

Note: If the printer has not been habitually used during 3-4 months, it is recommended to do lubrication operations.

|

|---|

BCN3D Set of Shims

Shims are elements that mechanically correct the Z offset when printing in Mirror or Duplication mode. These printing modes are available for all Sigmax versions, for the Sigma R19 and for the BCN3D Epsilon. Those Sigma users who have previous versions must update their firmware to 2.0.0 or higher to have them available. Visit our Support page to learn how to do it.

In these modes both toolheads work simultaneously, so it is key important to make sure both nozzle tips are exactly at the same height. Due to manufacturing and assembly tolerances the Z offset between tips can be up to 0.5mm. BCN3D printers automatically correct the offsets when printing in Mirror/Duplication Modes. However, this correction distorts the first layer of the model by repeating it as many time as needed. To avoid such distortion there are different options:

1. Enable raft in BCN3D Cura.

The offset will be corrected in the first layers of the raft, so the model won’t be affected by any Z offset.

2. Install shims to mechanically correct the Z offset.

Printing a raft takes time and spends material. For those users planning to use frequently the Mirror or Duplication modes, it is highly recommended to install the shims when it is suggested during the Printer Calibration process.

How to install it?

The installation process is step-guided by the printers. See how to install them in the Support website.

|

|---|

BCN3D Filaments PET-G - 2-85 mm - 2-3 kg - Black

Overview

PET-G (Polyethylene terephthalate glycol-modified) is a polyester thermoplastic characterised by a good balance of tensile strength and elongation at break. Its high resistance to water and chemicals makes it the material of choice for water-tight containers and protective cases.

PET-G is a versatile technical material, as easy to print as PLA, but with an improved balance of mechanical, chemical and thermal properties.

Compatibility: Find out the BCN3D printers and filaments compatibility

Applications

- Parts in contact with salts, acids and alkalis

- Functional prototypes and mechanical parts

- Waterproof applications

- Structural parts subject to mild stress

- Snap-fit joints

- Commonly used in beverage bottles

Properties

- Resistance to corrosive chemicals

- Good balance of strength, impact resistance and elongation at break

- Great dimensional stability and toughness

- Good glossy surface quality

- Good abrasion resistance

- Water and moisture barrier

- Withstand operating temperatures up to 70°C

- Low rate of ultrafine particles (UFP) and volatile organic compounds (VOC)

- Compatible with PVA supports

Technical information

Good balance of strength and ductility

PET-G parts are as strong as those made with PLA but offer a better mechanical profile. PET-G is not brittle, which means that it will not snap abruptly if pulled or bended, on the contrary, it will progressively bend and stretch until reaching it maximum elongation limit of 23%.

Resistant to chemicals and humidity

PET-G is highly resistant to chemicals and humidity, which allows for disinfection and cleaning without losing its mechanical properties to hydroalcoholic solutions.

Fast Tooling

Use it to fast-track the manufacture of jigs and fixtures for your production chain.

Mechanical parts

PET-G is ideal for end-use parts demanding mechanical and thermal properties.

|

|---|

BCN3D Filaments PET-G - 2-85 mm - 2-3 kg - White

Overview

PET-G (Polyethylene terephthalate glycol-modified) is a polyester thermoplastic characterised by a good balance of tensile strength and elongation at break. Its high resistance to water and chemicals makes it the material of choice for water-tight containers and protective cases.

PET-G is a versatile technical material, as easy to print as PLA, but with an improved balance of mechanical, chemical and thermal properties.

Compatibility: Find out the BCN3D printers and filaments compatibility

Applications

- Parts in contact with salts, acids and alkalis

- Functional prototypes and mechanical parts

- Waterproof applications

- Structural parts subject to mild stress

- Snap-fit joints

- Commonly used in beverage bottles

Properties

- Resistance to corrosive chemicals

- Good balance of strength, impact resistance and elongation at break

- Great dimensional stability and toughness

- Good glossy surface quality

- Good abrasion resistance

- Water and moisture barrier

- Withstand operating temperatures up to 70°C

- Low rate of ultrafine particles (UFP) and volatile organic compounds (VOC)

- Compatible with PVA supports

Technical information

Good balance of strength and ductility

PET-G parts are as strong as those made with PLA but offer a better mechanical profile. PET-G is not brittle, which means that it will not snap abruptly if pulled or bended, on the contrary, it will progressively bend and stretch until reaching it maximum elongation limit of 23%.

Resistant to chemicals and humidity

PET-G is highly resistant to chemicals and humidity, which allows for disinfection and cleaning without losing its mechanical properties to hydroalcoholic solutions.

Fast Tooling

Use it to fast-track the manufacture of jigs and fixtures for your production chain.

Mechanical parts

PET-G is ideal for end-use parts demanding mechanical and thermal properties.

|

|---|

BCN3D Sigmax R19 Maintenance Kit

The maintenance kit for the Sigmax contains the most used parts for maintenance or replacement of the printer. Maintenance work should be regular to keep the printer in good condition and achieve high quality prints at all times. Before making any repairs, it is important to turn off the printer and let it cool down.

What’s in the box:

· 4x Allen key (1)

· Nylon cleaning filament (2)

· Set of shims (3)

· Glass printing surface (4)

· x2 0.4mm Hotend by e3D (5)

· Grease 50ml (6)

· Solvent 12ml and Lubrication Oil 12ml (7)

· x4 Purger cloths (8)

· Magigoo: Build plate adhesive (9)

· Calibration gauge (10)

Maintenance operations that can be done with the kit:

· Lubricate and clean axes:

Periodically, according to the Maintenance Alerts via LCD screen, it is recommended to clean and grease the axes of the Sigmax with the lubrication kit to ensure a smooth and precise performance of its mechanical components. In the following manual you will find a detailed step by step guide on how to lubricate and clean the axes of your printer: Shortlink

· Clean the hotend:

To ensure an optimal printed parts, it is important to maintain the hotends correctly. Maintenance of the inside of the hotend should be performed once every month, every time you switch materials or if the nozzle is clogged. In the following manual you will find a detailed step by step guide on how to clean the hotend of your printer: Shortlink

· Installing shims:

Shims are elements that mechanically correct the Z offset when printing in Mirror or Duplication mode. In these modes both toolheads work simultaneously, so it is key important to make sure both nozzle tips are exactly at the same height. In the following manual you will find a detailed step by step guide on how to install the shims on your printer: Shortlink

· Change the hotend:

The maintenance kit includes 2 0,4mm e3D hotends. It is recommended to install a new hotend when you do not get a clean hotend when performing the “Nylon Cleaning Method” described on the “Clean the hotend” process. In the following manual you will find a detailed step by step guide on how to install a hotend on your printer: Shortlink

|

|---|

BCN3D Sigma R19 Maintenance Kit

The maintenance kit for the Sigma contains the most used parts for maintenance or replacement of the printer. Maintenance work should be regular to keep the printer in good condition and achieve high quality prints at all times. Before making any repairs, it is important to turn off the printer and let it cool down.

What’s in the box:

· 4x Allen key (1)

· Nylon cleaning filament (2)

· Set of shims (3)

· Glass printing surface (4)

· x2 0.4mm Hotend by e3D (5)

· Grease 50ml (6)

· Solvent 12ml and Lubrication Oil 12ml (7)

· x4 Purger cloths (8)

· Magigoo: Build plate adhesive (9)

· Calibration gauge (10)

Maintenance operations that can be done with the kit:

· Lubricate and clean axes:

Periodically, according to the Maintenance Alerts via LCD screen, it is recommended to clean and grease the axes of the Sigma with the lubrication kit to ensure a smooth and precise performance of its mechanical components. In the following manual you will find a detailed step by step guide on how to lubricate and clean the axes of your printer: Shortlink

· Clean the hotend:

To ensure an optimal printed parts, it is important to maintain the hotends correctly. Maintenance of the inside of the hotend should be performed once every month, every time you switch materials or if the nozzle is clogged. In the following manual you will find a detailed step by step guide on how to clean the hotend of your printer: Shortlink

· Installing shims:

Shims are elements that mechanically correct the Z offset when printing in Mirror or Duplication mode. In these modes both toolheads work simultaneously, so it is key important to make sure both nozzle tips are exactly at the same height. In the following manual you will find a detailed step by step guide on how to install the shims on your printer: Shortlink

· Change the hotend:

The maintenance kit includes 2 0,4mm e3D hotends. It is recommended to install a new hotend when you do not get a clean hotend when performing the “Nylon Cleaning Method” described on the “Clean the hotend” process. In the following manual you will find a detailed step by step guide on how to install a hotend on your printer: Shortlink

|

|---|

BCN3D Sigmax Printing Surface: Magnetic Glass Plate

Borosilicate glasses are known for having very low coefficients of thermal expansion, making them resistant to thermal shock, more so than any other common glass. This glass plate is compatible with all the BCN3D Sigma versions.

|

|---|

Sigmax R19 Abdeckungs-Gehäuse

Sigmax R19 Abdeckungs-Gehäuse/Enclosure

Kaufe dir hier das Abdeckungs-Gehäuses für deinen BCN Sigmax R19 und erhöhe deinen Anwendungskomfort. Durch einen geschlossenen Bauraum verringerst du Warping, schützt dein Arbeitsumfeld und reduzierst Geräusche.

Vorteile durch die Verwendung des Abdeckungs-Gehäuses für deinen BCN Sigmax R19:

- Konstante Innentemperatur zur Vermeidung von Warping/Verzug bei technischen Filament-Materialien wie ABS, Nylon und PET-G

- Schütze deine Arbeitsumgebung dank des HEPA-Filters vor potenziell schädlichen Partikeln

- Sehr empfehlenswert für Anwender, die große Teile 3D-drucken wollen, da es die die Erfolgswahrscheinlichkeit stark erhöht

- Der Sigmax R19 ist noch leiser danke der weiteren Geräuschreduktion

- Die Luft im Inneren des 3D-Druckers wird dank des HEPA-Filters beständig erneuert

- Es ist nicht erforderlich, den Sigmax R19 zu verschrauben, Löcher zu bohren oder zu modifizieren

- Die Abdeckung lässt sich leicht auf- und abbauen

Die Abdeckung wird zerlegt und mit einer Anleitung zur Montage geliefert. Im Lieferumfang sind alle notwendigen Werkzeugen zur Montage geliefert. Das Gehäuse ist nur mit der Sigma R19-Version kompatibel.

|

|---|

BCN3D Main Electronics Board

Mainboard for BCN3D Sigma/Sigmax, Sigma D25 and Epsilon series printers.

For the launch of the BCN3D Epsilon, BCN3D has redesigned and improved the mainboard. This version is fully compatible with previous models and has the same SKU: 10909

|

|---|

BCN3D Coupling Collect

Compatible with the BCN3D Sigma and the BCN3D Sigmax 3D printers.

Spare part for any hotend. This part locks the bowden tube while printing.

|

|---|

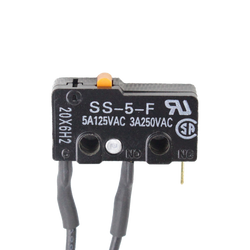

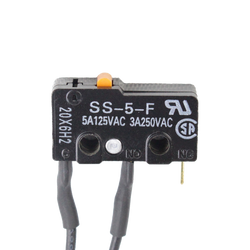

BCN3D Layer Fan - 40mm

This fan cools the filament as it is deposited, improving the surface quality and the ability to print bridges and overhangs. Its speed can be controlled as required, depending on the material being printed.

Measures: 40x40x10mm

Input: 24V

|

|---|

Artikel 1 - 41 von 41 gesamt.

Kategorien

3D Prima

3D Prima Accante

Accante Anet

Anet ANTCLABS

ANTCLABS Anycubic

Anycubic Artillery 3D

Artillery 3D BCN3D

BCN3D BIQU 3D

BIQU 3D Bondtech

Bondtech Buildtak

Buildtak Creality

Creality Creatbot

Creatbot Deltaco

Deltaco Flashforge

Flashforge Formbot

Formbot Intamsys

Intamsys Kingston

Kingston Lay-Filaments

Lay-Filaments Magigoo

Magigoo Mayku

Mayku Micro Swiss

Micro Swiss Monocure3D

Monocure3D Mosaic

Mosaic Myriwell

Myriwell NinjaTek

NinjaTek ohne Angabe

ohne Angabe Phaetus

Phaetus PrimaCreator

PrimaCreator Raise3D

Raise3D Sinterit

Sinterit Snapmaker

Snapmaker Sunlu

Sunlu SUNON

SUNON Taulman

Taulman Ultimaker

Ultimaker Voxelab

Voxelab Wanhao

Wanhao XYZ Printing

XYZ Printing ZMorph

ZMorph Zortrax

Zortrax