3D Drucker, Fertigmodelle, Bausätze und Zubehör

Flashforge Finder - Inventor 2 Touch Screen

Touch Screen for Flashforge Finder, New Finder and Inventor II.

|

|---|

XYZprinting Da Vinci Tough PLA Refill - 600g - Black

Refill Filament for the XYZPrinting da Vinci 1.0A, da Vinci 2.0A, da Vinci 1.0 AiO, da Vinci 1.1, da Vinci 1.0 Pro, da Vinci 1.0 Pro 3-in-1

Filament refills come in small sizes for space-economy and can be used at any given notice, allowing 3D printer operators and hobbyists to do their part for environmental protection while exercising their creative powers.

High Rigidity & Tensile Strengh

Tough PLA offers tensile strengh and high rigidity

Better Impact Resistance

Tough PLA can withstand a severe impact-load better than PLA.

Non-DEHP ( DEHP FREE )

XYZprintng Tough PLA has gone through rigourous testing by SGS laboratory to ensure that users are safe from harmful substances, such as DEHP and Heavy Metals.

|

|---|

Sinterit Studio Open - Software

SINTERIT Studio 2019 Profiles

Die Sinterit Studio Software wurde speziell für die Sinterit SLS 3D-Drucker Lisa und Lisa Pro entwickelt. Dank der Schritt-für-Schritt Vorgehensweise und der benutzerfreundlichen Oberfläche gestaltet sich dein Druckprozess einfach und schnell. Die Software führt Dich durch die Druckeinstellungen, hilft Dir deine Modelle anzuordnen und lässt Dich den Druckprozess mühelos überwachen und kontrollieren.

FEATURES:

- ermöglicht das Drucken von: PA12 Smooth, PA11 Onyx (nur Lisa Pro), Flexa Black / Grey, Pulver von Drittanbietern

- unterstützte Dateiformate: .STL, .OBJ, .3DS, .FBX, .DAE, .3MF

- Modell slicing

- Kalkulation des Pulververbrauchs

- verbesserte Modellausrichtung (Kollisionswarnung, Objektgruppierung)

- Überwachung und Kontrolle des Druckstatus

- neues Interface-Design für intuitiveren Prozess

- optimierte Performance - verbesserte Algorithmen für schnelleren Arbeitsablauf

- Datenübertragung an den 3D-Drucker per WiFi

|

|---|

Wanhao Duplicator D6 - 202-2GT-6 Zahnriemen

Wanhao Duplicator D6 - 202-2GT-6 Zahnriemen

Kaufe dir diesen 202-2GT-6 Zahnriemen für deinen Wanhao Duplicator D6.

|

|---|

3D-Druckbett für da Vinci 1-0 Pro- 3-in-1 Pro

3D-Druckbett für da Vinci 1.0 Pro, 3-in-1 Pro

Kaufe dir dieses 3D-Druckbett für deinen da Vinci 1.0 Pro, 3-in-1 Pro.

Druckbett für da Vinci 1.0 Pro, 3-in-1 Pro

Das Aluminium-Druckbett von XYZprinting sorgt für eine dauerhafte Heizfläche, die die Wärme schnell gleichmäßig verteilt und die Wahrscheinlichkeit von Warping verringert. Decke das Druckbett einfach mit unserem Abdeckband ab und beobachte, wie dein Druckbauteil mühelos auf dem Druckbett haftet.

- Maß 20 x 20 cm

- Teile-Nr: RS1AWXY102G

- EAN: 4715872742441

|

|---|

Y-Achsen-Schrittmotor Kabel - Wanhao Duplicator i3 Plus

Y-Achsen-Schrittmotor Kabel - Wanhao Duplicator i3 Plus

Dies ist ein Schrittmotor-Kabel für die Y-Achse deines Wanhao Duplicator i3 Plus.

|

|---|

PrimaSelect PLA Glossy - 1-75mm - 750 g - Polar White

PLA Glossy ist eine neue Art von PLA, die viel stärker ist als normales PLA und eine Hitzebeständigkeit von bis zu 75°C aufweist. Das bedeutet, dass Sie es sowohl für mechanische Teile verwenden können, als auch für Teile, die Sie im Sommer (z.B.) in einem heißen Auto benutzen wollen, ohne das Risiko, dass der Druck weich wird.

PLA Glossy ist ein einzigartiges Filament, da es eine glänzende Oberfläche hat. Es erzeugt Drucke mit einem extrem glänzenden/metallischen Finish, das wirklich hervorsticht.

PLA Glossy wird auf die gleiche Weise wie normales PLA verwendet, jedoch mit einem etwas höheren Temperaturbereich.

Die Drucktemperatur sollte zwischen 210 - 230°C liegen (typisch sind 220°C). Das Filament sollte mit einer beheizten Bauplatte verwendet werden, um beste Ergebnisse zu erzielen. Je nach Größe des Drucks können Sie es in einem Bereich von 20 - 90°C verwenden (typisch ist 60°C). Verwenden Sie eine normale Druckgeschwindigkeit von 40-60 mm/s.

Wir empfehlen die Verwendung von PrimaFIX auf der Baufläche für beste Haftung und um Warping zu vermeiden.

|

|---|

P120 Mainboard V3

Mainboard that fits to PrimaCreator P120 v3. (Blue version)

*Does not fit on V1 (White version)

There have been a changed on the latest models so before buying this board, check and compare with the board in your printer.

|

|---|

Micro Swiss - Vollständiges 0-4 mm Hotend aus Metall mit geschliztem Kühl-Block für Duplicater D6

Micro Swiss - Vollständiges 0,4 mm Hotend aus Metall mit geschliztem Kühl-Block für Duplicater D6

Dies ist der Micro Swiss All Metal Hotend Bausatz für deinen Wanhao Duplikator 6 mit den folgenden Verbesserungen:

- Geschlitztes Spannsystem

- Keine Stellschraube an der Wand und Beschädigung des Thermorohres

- Deutlich bessere Wärmeübertragung (das ist sehr wichtig!!!!!!)

- Einfachere Demontage und Justierung

- Präzise Kontrolle des Bohrungsdurchmessers

Micro Swiss All Metal Hotend Kit Eigenschaften:

- Dieses Upgrade beinhaltet ein modifiziertes Wärmedämmrohr und eine optimierte Nozzle mit umgestaltetem Kühlblock. Das Wärmedämmrohr besteht aus 2 unterschiedlichen Materialien. Die untere thermische Trennung ist aus Edelstahl, der kältere obere Teil aus Aluminium. Edelstahl wurde für die thermische Trennung verwendet, weil er eine niedrige Wärmeleitfähigkeit bietet. Das Aluminium für den oberen Teil besitzt eine viel bessere Wärmeleitfähigkeit und kann jegliche Wärme vom Filament abführen. Das All-Metall-Hotend ermöglicht es Dir, bei viel höheren Temperaturen zu drucken, als dies mit dem originalen PTFE-gefütterten Material möglich ist. Ein weiterer Vorteil eines All-Metall-Hotend-Designs ist eine konsequentere Schmelzkammerregelung. Während der langsamen Extrusionsgeschwindigkeit neigt die Übergangszone vom festen zum geschmolzenen Kunststoff dazu, nach oben zu kriechen, was zu fadenscheinigeren Drucken führt. Bei allen Metallausführungen ist eine Übergangszone immer konstant und befindet sich direkt an der Wärmebrücke. Bei einer schnelleren Extrusionsrate besitzt der PTFE-Schlauch nicht genügend Wärmeleitfähigkeit, um den gesamten austretenden Kunststoff richtig zu schmelzen. Bei Original-Extrudern geschieht diese Begrenzung bei 60 mm/s, je nach Nozzlegröße. Das All-Metall-Hotend löst dieses Problem, Kunststoff ist über seine gesamte Länge von einer wärmeleitenden Düse umgeben.

Das Kit enthält:

- 1 beschichtete, verschleißfeste Nozzle aus Messing

- 1 Thermorohr

- 1 geschlitzter Kühlblock

|

|---|

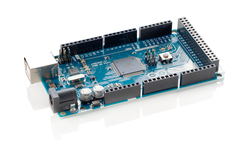

Ultimaker Original - Arduino Mega 2560

Ultimaker Original - Arduino Mega 2560

Kaufe dir dieses Arduino Mega 2560 für deinen Ultimaker Original.

Arduino Mega 2560 - Einfach mit einem USB-Kabel an einen Computer anschließen oder mit einem AC/DC-Adapter oder Akku betreiben. Der Mega ist mit den meisten Boards kompatibel, die für den Arduino Duemilanove oder Diecimila entwickelt wurden.

|

|---|

PrimaCreator EasyPrint FLEX 95A - 1-75 mm - 500g - grün

EasyPrint FLEX TPU – Flexibles Filament von PrimaCreator

EasyPrint FLEX TPU ist das neuestes flexible Filament von PrimaCreator. Bei der Entwicklung dieses 3D Drucker Filaments lag der Fokus auf Haltbarkeit, Flexibilität und Benutzerfreundlichkeit. Das Filament besteht aus TPU (Thermoplastisches Polyurethan), einem der am häufigsten verwendeten Polymere für flexible 3D Druck-Materialien. Profitiere jetzt von den Vorteilen von TPU und einer einfachen Verarbeitung. Das Material besitzt nur ein minimales Verziehen, geringe Material-Schrumpfung, ist sehr langlebig und beständig gegen die meisten Chemikalien und Öle.

Warum sollte ich EasyPrint FLEX TPU als flexibles Filament verwenden?

- Aufgrund der Shore-Härte von 95A ist es sehr einfach zu verarbeiten

- 1 kg Material auf deiner Spule

- Perfekt aufgewickeltes Filament, kein Verknoten mehr

- Einfach zu verarbeiten mit einer großen Temperaturspanne von 180 – 230 °C

- Perfekt gleichmäßig rund

- Optimale Durchmessertoleranz innerhalb von +/-0,05 mm

- Einfaches Ablesen des Filament-Status über die intelligente Längenanzeige

- Ideal für den Einsatz im Freien, da UV-beständig

Flexibles Filament mit hoher Shore Härte ermöglicht eine einfache Verarbeitung

EasyPrint FLEX TPU besitzt eine Shore Härte von 95 A. Dies entspricht in etwa dem Gummiabsatz eines Schuhs oder eines Einkaufsrades. Weiterhin ist das flexible Filament dank der relativ hohen Shore-Härte sehr einfach mit den meisten 3D-Druckern zu verarbeiten. Verwende es auch mit deinen Bowden-Setup-3D-Druckern, wie z.B. Ultimaker oder BCN3D Sigma. Das Filament benötigt keinen 3D-Drucker mit Direktantrieb (DirectDrive-Extruder).

„Semi-flex“ Filament ermöglicht vielfältige Anwendungen

Die semi-flex Formel in diesem Filament ist wunderbar. Steuere deine 3D-Drucke und ihre Flexibilität einfach über die innere Füllung deiner Bauteile. Wünschst du dir eine flexible, einfach faltbare Struktur, welche sich leicht zusammendrücken lässt, die immer wieder in ihre ursprüngliche Form zurückkehrt? Dann ist EasyPrint FLEX TPU dein Filament. 3D-Drucke es einfach mit weniger Füllung. Wenn du mehr Infill nutzt, erhältst du einen 3D-Druck, der eher Hartgummi ähnelt (Think Care Reifen). Profitiere mit PrimaCreator EasyPrint FLEX TPU von einem sehr breiten Anwendungsspektrum. 3D-Drucke beispielsweise Griffe für Fahrräder, Stoßdämpfer, Gummidichtungen und Einlegesohlen für Schuhe. PrimaCreator TPU verfügt über eine massive Reißdehnung von 400%.

Geringe Materialschrumpfung – weniger Warping

Durch die sehr geringe Material-Schrumpfung ist EasyPrint FLEX TPU sehr einfach mit allen FDM/FFF-Druckern zu verarbeiten. EasyPrint FLEX neigt nur sehr wenig zum Verziehen & Warping. Der 3D-Druck funktioniert auch gut ohne beheizte Bauplattform. Dennoch empfehlen wir für größere 3D Drucke und besten Ergebnisse eine beheizte Bauplatte. Dabei sorgen die Temperatureinstellung von 40-60 °C und eine Beschichtung mit PrimaFIX für eine sehr gute Haftung der ersten Schicht.

Achte auf eine trockene Lagerung von deinem TPU Filament

Bitte beachte, dass TPU hygroskopisch ist, d.h. zur Absorption von Wasser neigt. Deshalb lagere es luftdicht und vor Feuchtigkeit geschützt in einem geschlossen Behälter oder Beutel mit Luftentfeuchter. Sollte dein TPU Filament einmal feucht werden, so kannst du es jederzeit für ca. 1 Stunde bei 70° C in deinem Back-Ofen trocknen. Anschließend ist das Filament trocken und lässt sich wie neu verarbeiten.

Mit EasyPrint FLEX-Filament gelingen dir mehr 3D-Drucke!

TPU-Filament: Tipps für gute 3D-Druck-Ergebnisse

- 3D-Druck mit niedriger Geschwindigkeit, 15-30 mm/s

- Verwende ein beheiztes Druckbett, wenn vorhanden

- Halte dein Filament immer trocken gelagert

|

|---|

Ultimaker 2+ - Kabel für beheiztes Druckbett

Ultimaker 2+ - Kabel für beheiztes Druckbett

Kaufe dir dieses Kabel für ein beheiztes Druckbett für deinen Ultimaker 2+.

|

|---|

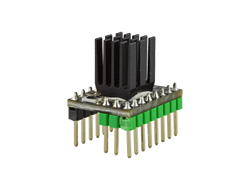

Creality 3D Ender-3 Silent Mainboard V4-2-7 - 32-bit

32-bit Mainboard for Creality Ender-3.

Equipped with STM32F103 controller and TMC2225 stepper drivers.

|

|---|

MK8 gehärteter Stahl-Nozzle 0-6 mm - 1 Stk-

MK8 nozzle made from hardened steel. 0,6 mm

Fits to: Creality CR-10 series, MakerBot Replicator 2, CraftBot series

The premium nozzles from PrimaCreator are a series of replacement nozzles that can make more difference for the result than you may think. To have a high-quality nozzle is like having a sharp pencil, you need it to get a great print.

All nozzles from PrimaCreator are made from the best high-quality brass or steel (depending on type) and are completed in a state of the art factory. All nozzles are manufactured with a tolerance of less than ± 0.01 mm. This means that your filament will have a very smooth and clear surface while extruding which, of course, results in better prints.

For best results and optimal print quality, we highly recommend that you re-level your build plate after changing to a new nozzle. Note that a PrimaCreator nozzle might be compatible with your printer, but the distance between nozzle and build plate must be adjusted.

The process of making a PrimaCreator nozzle begins with a selected high-quality material. When the material reaches the factory, there is first an optical inspection made of the material that are going to be used for each batch of nozzles. Then it´s time to clamp the material, in other words, make it into a long rod. In our process this only is done once, in many other (cheaper) cases, this process must be repeated several times, often as many as 3-4 times and yet you don´t get the same results.

After this process, the material goes through an ultrasonic cleaning bath and after that it is cleaned again and protected against surface oxidation.

The nozzle will now take shape with millimeter precision, the tolerance is less than ± 0.01 mm.

The process of removing sharp edges from the nozzles is a very important step as this makes up a big part of the result. If there is to much sharp edges left on the nozzle it will make the nozzle more prone to clog. So it´s essential that the nozzle is very smooth and clean before it is used. In every batch a few nozzles are selected and cut in half to make sure that every specification is met, and that the surface is in perfect condition.

The nozzles are then checked for one last time and packed individually in a protective box – ready to be shipped to you.

The series of nozzles from PrimaCreator is the perfect choice for people who only wants the best and at a great value!

Marks/dots on Nozzle = Size

- 0 = 0.20mm

- 3 = 0.40mm

- 4 = 0.60mm

- 5 = 0.80mm

|

|---|

Raise3D - Schnellkupplung-Filamentführung

Raise3D - Schnellkupplung-Filamentführung

Dies ist eine Schnellkupplung-Filamentführung für deinen Raise3D 3D-Drucker.

|

|---|

Kategorien

3D Prima

3D Prima Accante

Accante Anet

Anet ANTCLABS

ANTCLABS Anycubic

Anycubic Artillery 3D

Artillery 3D BCN3D

BCN3D BIQU 3D

BIQU 3D Bondtech

Bondtech Buildtak

Buildtak Creality

Creality Creatbot

Creatbot Deltaco

Deltaco Flashforge

Flashforge Formbot

Formbot Intamsys

Intamsys Kingston

Kingston Lay-Filaments

Lay-Filaments Magigoo

Magigoo Mayku

Mayku Micro Swiss

Micro Swiss Monocure3D

Monocure3D Mosaic

Mosaic Myriwell

Myriwell NinjaTek

NinjaTek ohne Angabe

ohne Angabe Phaetus

Phaetus PrimaCreator

PrimaCreator Raise3D

Raise3D Sinterit

Sinterit Snapmaker

Snapmaker Sunlu

Sunlu SUNON

SUNON Taulman

Taulman Ultimaker

Ultimaker Voxelab

Voxelab Wanhao

Wanhao XYZ Printing

XYZ Printing ZMorph

ZMorph Zortrax

Zortrax