Produkte von PrimaCreator aus der Kategorie Filament & Resin > Filament > PLA > PrimaSELECT

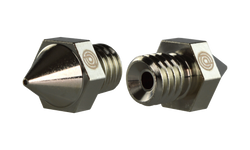

PrimaCreator Zortrax Hardened Nozzle for M200-M300 - 0-8 mm - 1 pcs

Zortrax Hardened Nozzle for M200/M300 - 0,8 mm - 1 pcs

Compatible with: Zortrax M200, M300, Afinia H479, H480, Up Plus 2

The premium nozzles from PrimaCreator are a series of replacement nozzles that can make more difference for the result than you may think. To have a high-quality nozzle is like having a sharp pencil, you need it to get a great print.

All nozzles from PrimaCreator are made from the best high-quality brass or steel (depending on type) and are completed in a state of the art factory. All nozzles are manufactured with a tolerance of less than ± 0.01 mm. This means that your filament will have a very smooth and clear surface while extruding which, of course, results in better prints.

For best results and optimal print quality, we highly recommend that you re-level your build plate after changing to a new nozzle. Note that a PrimaCreator nozzle might be compatible with your printer, but the distance between nozzle and build plate must be adjusted.

The process of making a PrimaCreator nozzle begins with a selected high-quality material. When the material reaches the factory, there is first an optical inspection made of the material that are going to be used for each batch of nozzles. Then it´s time to clamp the material, in other words, make it into a long rod. In our process this only is done once, in many other (cheaper) cases, this process must be repeated several times, often as many as 3-4 times and yet you don´t get the same results.

After this process, the material goes through an ultrasonic cleaning bath and after that it is cleaned again and protected against surface oxidation.

The nozzle will now take shape with millimeter precision, the tolerance is less than ± 0.01 mm.

The process of removing sharp edges from the nozzles is a very important step as this makes up a big part of the result. If there is to much sharp edges left on the nozzle it will make the nozzle more prone to clog. So it´s essential that the nozzle is very smooth and clean before it is used. In every batch a few nozzles are selected and cut in half to make sure that every specification is met, and that the surface is in perfect condition.

The nozzles are then checked for one last time and packed individually in a protective box – ready to be shipped to you.

The series of nozzles from PrimaCreator is the perfect choice for people who only wants the best and at a great value!

Marks/dots on Nozzle = Size

- 0 = 0.20mm

- 3 = 0.40mm

- 4 = 0.60mm

- 5 = 0.80mm

|

|---|

PrimaCreator Zortrax Hardened Nozzle for M200-M300 - 0-6 mm - 1 pcs

Zortrax Hardened Nozzle for M200/M300 - 0,6 mm - 1 pcs

Compatible with: Zortrax M200, M300, Afinia H479, H480, Up Plus 2

The premium nozzles from PrimaCreator are a series of replacement nozzles that can make more difference for the result than you may think. To have a high-quality nozzle is like having a sharp pencil, you need it to get a great print.

All nozzles from PrimaCreator are made from the best high-quality brass or steel (depending on type) and are completed in a state of the art factory. All nozzles are manufactured with a tolerance of less than ± 0.01 mm. This means that your filament will have a very smooth and clear surface while extruding which, of course, results in better prints.

For best results and optimal print quality, we highly recommend that you re-level your build plate after changing to a new nozzle. Note that a PrimaCreator nozzle might be compatible with your printer, but the distance between nozzle and build plate must be adjusted.

The process of making a PrimaCreator nozzle begins with a selected high-quality material. When the material reaches the factory, there is first an optical inspection made of the material that are going to be used for each batch of nozzles. Then it´s time to clamp the material, in other words, make it into a long rod. In our process this only is done once, in many other (cheaper) cases, this process must be repeated several times, often as many as 3-4 times and yet you don´t get the same results.

After this process, the material goes through an ultrasonic cleaning bath and after that it is cleaned again and protected against surface oxidation.

The nozzle will now take shape with millimeter precision, the tolerance is less than ± 0.01 mm.

The process of removing sharp edges from the nozzles is a very important step as this makes up a big part of the result. If there is to much sharp edges left on the nozzle it will make the nozzle more prone to clog. So it´s essential that the nozzle is very smooth and clean before it is used. In every batch a few nozzles are selected and cut in half to make sure that every specification is met, and that the surface is in perfect condition.

The nozzles are then checked for one last time and packed individually in a protective box – ready to be shipped to you.

The series of nozzles from PrimaCreator is the perfect choice for people who only wants the best and at a great value!

Marks/dots on Nozzle = Size

- 0 = 0.20mm

- 3 = 0.40mm

- 4 = 0.60mm

- 5 = 0.80mm

|

|---|

PrimaCreator Zortrax Hardened Nozzle for M200-M300 - 0-4 mm - 1 pcs

Zortrax Hardened Nozzle for M200/M300 - 0,4 mm - 1 pcs

Compatible with: Zortrax M200, M300, Afinia H479, H480, Up Plus 2

The premium nozzles from PrimaCreator are a series of replacement nozzles that can make more difference for the result than you may think. To have a high-quality nozzle is like having a sharp pencil, you need it to get a great print.

All nozzles from PrimaCreator are made from the best high-quality brass or steel (depending on type) and are completed in a state of the art factory. All nozzles are manufactured with a tolerance of less than ± 0.01 mm. This means that your filament will have a very smooth and clear surface while extruding which, of course, results in better prints.

For best results and optimal print quality, we highly recommend that you re-level your build plate after changing to a new nozzle. Note that a PrimaCreator nozzle might be compatible with your printer, but the distance between nozzle and build plate must be adjusted.

The process of making a PrimaCreator nozzle begins with a selected high-quality material. When the material reaches the factory, there is first an optical inspection made of the material that are going to be used for each batch of nozzles. Then it´s time to clamp the material, in other words, make it into a long rod. In our process this only is done once, in many other (cheaper) cases, this process must be repeated several times, often as many as 3-4 times and yet you don´t get the same results.

After this process, the material goes through an ultrasonic cleaning bath and after that it is cleaned again and protected against surface oxidation.

The nozzle will now take shape with millimeter precision, the tolerance is less than ± 0.01 mm.

The process of removing sharp edges from the nozzles is a very important step as this makes up a big part of the result. If there is to much sharp edges left on the nozzle it will make the nozzle more prone to clog. So it´s essential that the nozzle is very smooth and clean before it is used. In every batch a few nozzles are selected and cut in half to make sure that every specification is met, and that the surface is in perfect condition.

The nozzles are then checked for one last time and packed individually in a protective box – ready to be shipped to you.

The series of nozzles from PrimaCreator is the perfect choice for people who only wants the best and at a great value!

Marks/dots on Nozzle = Size

- 0 = 0.20mm

- 3 = 0.40mm

- 4 = 0.60mm

- 5 = 0.80mm

|

|---|

PrimaCreator Zortrax Brass Nozzle for M200-M300 - 0-6 mm - 1 pcs

Zortrax Brass Nozzle for 0,6 mm

Compatible with: Zortrax M200, M300, Afinia H479, H480, Up Plus 2

The premium nozzles from PrimaCreator are a series of replacement nozzles that can make more difference for the result than you may think. To have a high-quality nozzle is like having a sharp pencil, you need it to get a great print.

All nozzles from PrimaCreator are made from the best high-quality brass or steel (depending on type) and are completed in a state of the art factory. All nozzles are manufactured with a tolerance of less than ± 0.01 mm. This means that your filament will have a very smooth and clear surface while extruding which, of course, results in better prints.

For best results and optimal print quality, we highly recommend that you re-level your build plate after changing to a new nozzle. Note that a PrimaCreator nozzle might be compatible with your printer, but the distance between nozzle and build plate must be adjusted.

The process of making a PrimaCreator nozzle begins with a selected high-quality material. When the material reaches the factory, there is first an optical inspection made of the material that are going to be used for each batch of nozzles. Then it´s time to clamp the material, in other words, make it into a long rod. In our process this only is done once, in many other (cheaper) cases, this process must be repeated several times, often as many as 3-4 times and yet you don´t get the same results.

After this process, the material goes through an ultrasonic cleaning bath and after that it is cleaned again and protected against surface oxidation.

The nozzle will now take shape with millimeter precision, the tolerance is less than ± 0.01 mm.

The process of removing sharp edges from the nozzles is a very important step as this makes up a big part of the result. If there is to much sharp edges left on the nozzle it will make the nozzle more prone to clog. So it´s essential that the nozzle is very smooth and clean before it is used. In every batch a few nozzles are selected and cut in half to make sure that every specification is met, and that the surface is in perfect condition.

The nozzles are then checked for one last time and packed individually in a protective box – ready to be shipped to you.

The series of nozzles from PrimaCreator is the perfect choice for people who only wants the best and at a great value!

Marks/dots on Nozzle = Size

- 0 = 0.20mm

- 3 = 0.40mm

- 4 = 0.60mm

- 5 = 0.80mm

|

|---|

PrimaCreator Zortrax Brass Nozzle for M200-M300 - 0-6 mm - 1 pcs

Zortrax Brass Nozzle for 0,6 mm

Compatible with: Zortrax M200, M300, Afinia H479, H480, Up Plus 2

The premium nozzles from PrimaCreator are a series of replacement nozzles that can make more difference for the result than you may think. To have a high-quality nozzle is like having a sharp pencil, you need it to get a great print.

All nozzles from PrimaCreator are made from the best high-quality brass or steel (depending on type) and are completed in a state of the art factory. All nozzles are manufactured with a tolerance of less than ± 0.01 mm. This means that your filament will have a very smooth and clear surface while extruding which, of course, results in better prints.

For best results and optimal print quality, we highly recommend that you re-level your build plate after changing to a new nozzle. Note that a PrimaCreator nozzle might be compatible with your printer, but the distance between nozzle and build plate must be adjusted.

The process of making a PrimaCreator nozzle begins with a selected high-quality material. When the material reaches the factory, there is first an optical inspection made of the material that are going to be used for each batch of nozzles. Then it´s time to clamp the material, in other words, make it into a long rod. In our process this only is done once, in many other (cheaper) cases, this process must be repeated several times, often as many as 3-4 times and yet you don´t get the same results.

After this process, the material goes through an ultrasonic cleaning bath and after that it is cleaned again and protected against surface oxidation.

The nozzle will now take shape with millimeter precision, the tolerance is less than ± 0.01 mm.

The process of removing sharp edges from the nozzles is a very important step as this makes up a big part of the result. If there is to much sharp edges left on the nozzle it will make the nozzle more prone to clog. So it´s essential that the nozzle is very smooth and clean before it is used. In every batch a few nozzles are selected and cut in half to make sure that every specification is met, and that the surface is in perfect condition.

The nozzles are then checked for one last time and packed individually in a protective box – ready to be shipped to you.

The series of nozzles from PrimaCreator is the perfect choice for people who only wants the best and at a great value!

Marks/dots on Nozzle = Size

- 0 = 0.20mm

- 3 = 0.40mm

- 4 = 0.60mm

- 5 = 0.80mm

|

|---|

PrimaCreator FEP Film Roll for 3D Printers - 30 x 160 cm

PrimaCreator FEP-Folienrolle für 3D-Drucker

Rolle mit hochwertiger PrimaCreator FEP-Folie.

PrimaCreator FEP-Folien sind aus hochwertigem Material gefertigt, um eine hohe Lichtdurchlässigkeit und gute Zuverlässigkeit zu gewährleisten.

Um die Folie vor Falten und Kratzern zu schützen, ist jede Folie beidseitig mit einer Schutzfolie versehen und in einem stabilen Kartonschlauch verpackt.

Diese FEP-Folie lässt sich leicht auf nahezu jeden 3D-Drucker zuschneiden.

Spezifikationen:

- Größe: 30x160cm.

- Stärke: 0,15-0,2mm.

- Lichtdurchlässigkeit: 95%.

Eine Rolle (30x160cm) reicht für:

- 16 Blatt für 5,5-6,1 LCD Drucker (140x200mm).

- 8 Blatt für 8,9 LCD Drucker (200x260mm).

- 6 Blatt für 10,1 LCD Drucker (240x300mm).

- 4 Blatt für 13,3 LCD Drucker (260x380mm).

Bitte entfernen Sie vor der Verwendung die Schutzfolie von beiden Seiten der FEP-Platte.

|

|---|

PrimaCreator FEP-Folienblätter für 3D-Drucker - 140 x 200 mm - 5er-Pack

PrimaCreator FEP-Folienblätter für 3D-Drucker

5-Pack hochwertige PrimaCreator FEP-Folienblätter.

PrimaCreator FEP-Folienblätter sind aus hochwertigem Material gefertigt, um eine hohe Lichtdurchlässigkeit und gute Zuverlässigkeit zu gewährleisten.

Um die Blätter vor Falten und Kratzern zu schützen, ist jedes Blatt beidseitig mit einer Schutzfolie versehen und in einem Schutzumschlag verpackt.

Die Blätter passen für die meisten 3D-Drucker mit 5,5-6,1 LCDs.

Spezifikationen:

- Größe: 140x200mm.

- Dicke: 0,15-0,2mm.

- Lichtdurchlässigkeit: 95%.

- 5 Blätter / Paket.

Kompatibel mit:

- Anycubic Photon

- Anycubic Photon S

- Anycubic Photon Mono SE

- Creality LD-001

- Creality LD-002

- Creality LD-002R

- Creality LD- 002H

- Elegoo Mars

- Elegoo Mars Pro

- Elegoo Mars 2

- Elegoo Mars 2 Pro

- EPAX X1-Serie

- EPAX E6

- Monoprice Mini Deluxe

- Phrozen Shuffle

- Phrozen Shuffle 4K

- Phrozen Sonic 4K

- Phrozen Sonic Mini

- Phrozen Sonic Mini 4K

- Qidi Tech Shadow 5. 5

- Qidi Tech Shadow 5.5S

- Wanhao Duplicator 7

- Wanhao Duplicator 7 Pro

- und viele andere 3D-Drucker mit 5,5-6,1 LCDs.

Bitte entfernen Sie vor dem Gebrauch die Schutzfolie von beiden Seiten der FEP-Platte.

|

|---|

PrimaSelect PLA Tough - 2-85mm - 750 g - weiss

Bei SELECT Tough PLA haben wir die bekannte SELECT PLA Formel verwendet und sie verändert. Das Ergebnis ist ein neuartiges Filament, dass wir Tough nennen.

Es wurde auf Stärke und Haltbarkeit hin entwickelt und nimmt den Kampf gegen ABS auf.

Tough PLA hat eine viel höhere Schlagzähigkeit als normales PLA und die Steifigkeit ist viel besser als ABS.

Tough PLA ist ideal für den Druck großer/sehr großer Drucke, wie Prototypen und Funktionsobjekte. Und das alles, ohne sich Gedanken über Warping und Delamination zu machen. Das Material ist genauso einfach zu drucken wie unser reguläres PLA - nur viel stärker.

Tough PLA druckt wie reguläres PLA mit einer Temperatur von 210°C-225°C je nach Modell, Drucker und Farbe.

Lüfter sollten auf 100% eingestellt werden und die beheizte Bauplatte sollte bei einer Temperatur von 60°C-80°C verwendet werden und wir empfehlen PrimaFIX für zusätzliche Haftung.

|

|---|

PrimaSelect PLA Tough - 2-85mm - 750 g - Schwarz

Bei SELECT Tough PLA haben wir die bekannte SELECT PLA Formel verwendet und sie verändert. Das Ergebnis ist ein neuartiges Filament, dass wir Tough nennen.

Es wurde auf Stärke und Haltbarkeit hin entwickelt und nimmt den Kampf gegen ABS auf.

Tough PLA hat eine viel höhere Schlagzähigkeit als normales PLA und die Steifigkeit ist viel besser als ABS.

Tough PLA ist ideal für den Druck großer/sehr großer Drucke, wie Prototypen und Funktionsobjekte. Und das alles, ohne sich Gedanken über Warping und Delamination zu machen. Das Material ist genauso einfach zu drucken wie unser reguläres PLA - nur viel stärker.

Tough PLA druckt wie reguläres PLA mit einer Temperatur von 210°C-225°C je nach Modell, Drucker und Farbe.

Lüfter sollten auf 100% eingestellt werden und die beheizte Bauplatte sollte bei einer Temperatur von 60°C-80°C verwendet werden und wir empfehlen PrimaFIX für zusätzliche Haftung.

|

|---|

PrimaSelect PLA Tough - 1-75mm - 750 g - blau

Bei SELECT Tough PLA haben wir die bekannte SELECT PLA Formel verwendet und sie verändert. Das Ergebnis ist ein neuartiges Filament, dass wir Tough nennen.

Es wurde auf Stärke und Haltbarkeit hin entwickelt und nimmt den Kampf gegen ABS auf.

Tough PLA hat eine viel höhere Schlagzähigkeit als normales PLA und die Steifigkeit ist viel besser als ABS.

Tough PLA ist ideal für den Druck großer/sehr großer Drucke, wie Prototypen und Funktionsobjekte. Und das alles, ohne sich Gedanken über Warping und Delamination zu machen. Das Material ist genauso einfach zu drucken wie unser reguläres PLA - nur viel stärker.

Tough PLA druckt wie reguläres PLA mit einer Temperatur von 210°C-225°C je nach Modell, Drucker und Farbe.

Lüfter sollten auf 100% eingestellt werden und die beheizte Bauplatte sollte bei einer Temperatur von 60°C-80°C verwendet werden und wir empfehlen PrimaFIX für zusätzliche Haftung.

|

|---|

PrimaSelect PLA Tough - 1-75mm - 750 g - Rot

Bei SELECT Tough PLA haben wir die bekannte SELECT PLA Formel verwendet und sie verändert. Das Ergebnis ist ein neuartiges Filament, dass wir Tough nennen.

Es wurde auf Stärke und Haltbarkeit hin entwickelt und nimmt den Kampf gegen ABS auf.

Tough PLA hat eine viel höhere Schlagzähigkeit als normales PLA und die Steifigkeit ist viel besser als ABS.

Tough PLA ist ideal für den Druck großer/sehr großer Drucke, wie Prototypen und Funktionsobjekte. Und das alles, ohne sich Gedanken über Warping und Delamination zu machen. Das Material ist genauso einfach zu drucken wie unser reguläres PLA - nur viel stärker.

Tough PLA druckt wie reguläres PLA mit einer Temperatur von 210°C-225°C je nach Modell, Drucker und Farbe.

Lüfter sollten auf 100% eingestellt werden und die beheizte Bauplatte sollte bei einer Temperatur von 60°C-80°C verwendet werden und wir empfehlen PrimaFIX für zusätzliche Haftung.

|

|---|

PrimaSelect PLA Tough - 1-75mm - 750 g - dunkelgrau

Bei SELECT Tough PLA haben wir die bekannte SELECT PLA Formel verwendet und sie verändert. Das Ergebnis ist ein neuartiges Filament, dass wir Tough nennen.

Es wurde auf Stärke und Haltbarkeit hin entwickelt und nimmt den Kampf gegen ABS auf.

Tough PLA hat eine viel höhere Schlagzähigkeit als normales PLA und die Steifigkeit ist viel besser als ABS.

Tough PLA ist ideal für den Druck großer/sehr großer Drucke, wie Prototypen und Funktionsobjekte. Und das alles, ohne sich Gedanken über Warping und Delamination zu machen. Das Material ist genauso einfach zu drucken wie unser reguläres PLA - nur viel stärker.

Tough PLA druckt wie reguläres PLA mit einer Temperatur von 210°C-225°C je nach Modell, Drucker und Farbe.

Lüfter sollten auf 100% eingestellt werden und die beheizte Bauplatte sollte bei einer Temperatur von 60°C-80°C verwendet werden und wir empfehlen PrimaFIX für zusätzliche Haftung.

|

|---|

PrimaSelect PLA Tough - 1-75mm - 750 g - weiss

Bei SELECT Tough PLA haben wir die bekannte SELECT PLA Formel verwendet und sie verändert. Das Ergebnis ist ein neuartiges Filament, dass wir Tough nennen.

Es wurde auf Stärke und Haltbarkeit hin entwickelt und nimmt den Kampf gegen ABS auf.

Tough PLA hat eine viel höhere Schlagzähigkeit als normales PLA und die Steifigkeit ist viel besser als ABS.

Tough PLA ist ideal für den Druck großer/sehr großer Drucke, wie Prototypen und Funktionsobjekte. Und das alles, ohne sich Gedanken über Warping und Delamination zu machen. Das Material ist genauso einfach zu drucken wie unser reguläres PLA - nur viel stärker.

Tough PLA druckt wie reguläres PLA mit einer Temperatur von 210°C-225°C je nach Modell, Drucker und Farbe.

Lüfter sollten auf 100% eingestellt werden und die beheizte Bauplatte sollte bei einer Temperatur von 60°C-80°C verwendet werden und wir empfehlen PrimaFIX für zusätzliche Haftung.

|

|---|

PrimaSelect PLA Tough - 1-75mm - 750 g - Schwarz

Bei SELECT Tough PLA haben wir die bekannte SELECT PLA Formel verwendet und sie verändert. Das Ergebnis ist ein neuartiges Filament, dass wir Tough nennen.

Es wurde auf Stärke und Haltbarkeit hin entwickelt und nimmt den Kampf gegen ABS auf.

Tough PLA hat eine viel höhere Schlagzähigkeit als normales PLA und die Steifigkeit ist viel besser als ABS.

Tough PLA ist ideal für den Druck großer/sehr großer Drucke, wie Prototypen und Funktionsobjekte. Und das alles, ohne sich Gedanken über Warping und Delamination zu machen. Das Material ist genauso einfach zu drucken wie unser reguläres PLA - nur viel stärker.

Tough PLA druckt wie reguläres PLA mit einer Temperatur von 210°C-225°C je nach Modell, Drucker und Farbe.

Lüfter sollten auf 100% eingestellt werden und die beheizte Bauplatte sollte bei einer Temperatur von 60°C-80°C verwendet werden und wir empfehlen PrimaFIX für zusätzliche Haftung.

|

|---|

PrimaCreator Raise3D Pro2 Ruby Nozzle 0-6 mm - 1 pcs

Raise3D Pro2 Ruby Nozzle 0,6 mm - 1 pcs

Fits: Raise3D Pro2 nozzle, Pro2 Plus nozzle , E2 nozzle

The PrimaCreator Ruby Nozzle is the latest addition to the range of PrimaCreator nozzles.

A regular brass nozzle is most often recommended as they have a superior conductivity when it comes to heat. But a brass nozzle has its draw backs. If you want to print with an abrasive material like carbon or glow in the dark filament a regular brass nozzle will wear out in a very short time. This is why you can choose to use a hardened steel nozzle, it will not wear out as quick as a brass nozzle but it´s made of steel and as a material it´s not optimized for being used as an “every day nozzle” due to the fact that the heat conductivity isn´t as good as in a brass nozzle.

The most logical solution would be to have the best of both worlds.

Enter the PrimaCreator Ruby Nozzle.

In the best nozzle we ever produced we have the same high-quality brass as in our regular nozzles but in addition to this we have also added a small ruby gemstone at the tip of the nozzle. This transforms a regular brass nozzle to a nozzle you can use with your standard filament like PLA, ABS, PETG and so on to the more abrasive ones like carbon filled filament, metal, glow in the dark, wood, well, most types of “nozzle killer filament” you can think about that are currently on the market.

Finally, you can use one nozzle for all your materials.

All ruby nozzles from PrimaCreator are made from the best high-quality brass with a genuine ruby tip. They are completed in a state-of-the-art factory. All nozzles are manufactured with a tolerance of less than ± 0.01 mm. This means that your filament will have a very smooth and clear surface while extruding which, of course, results in better prints.

For best results and optimal print quality, we highly recommend that you re-level your build plate after changing to a new nozzle. Note that a Prima Creator nozzle might be compatible with your printer, but the distance between nozzle and build plate must be adjusted.

The process of making a Prima Creator nozzle begins with a selected high-quality material. When the material reaches the factory, there is first an optical inspection made of the material that are going to be used for each batch of nozzles. Then it´s time to clamp the material, in other words, make it into a long rod. In our process this only is done once, in many other (cheaper) cases, this process must be repeated several times, often as many as 3-4 times and yet you don´t get the same results.

After this process, the material goes through an ultrasonic cleaning bath and after that it is cleaned again and protected against surface oxidation.

The nozzle will now take shape with millimeter precision, the tolerance is less than ± 0.01 mm.

The process of removing sharp edges from the nozzles is a very important step as this makes up a big part of the result. If there is too much sharp edges left on the nozzle it will make the nozzle more prone to clog. So, it´s essential that the nozzle is very smooth and clean before it is used. In every batch a few nozzles are selected and cut in half to make sure that every specification is met, and that the surface is in perfect condition.

The nozzles are then checked for one last time and packed individually in a protective box – ready to be shipped to you.

The ruby nozzle from PrimaCreator is the perfect choice for people who only wants the best and at a great value!

Why should I use a ruby nozzle?

- All filaments, one nozzle

- Extreme durability

- Perfect for very abrasive filaments like carbon, glow in the dark, glass fiber, metal, wood.

- Perfect diameter without jagged edges equals better print quality

|

|---|

PrimaCreator Raise3D Pro2 Nickel Plated Copper Nozzle 0-8 mm - 1 pcs

Raise3D Pro2 Nickel Plated Copper Nozzle 0,8 mm - 1 pcs

Fits to: Raise3D Pro2, Pro2 Plus and E2

The premium nozzles from PrimaCreator are a series of replacement nozzles that can make more difference for the result than you may think. To have a high-quality nozzle is like having a sharp pencil, you need it to get a great print.

All nozzles from PrimaCreator are made from the best high-quality brass, copper or steel (depending on type) and are completed in a state of the art factory. All nozzles are manufactured with a tolerance of less than ± 0.01 mm. This means that your filament will have a very smooth and clear surface while extruding which, of course, results in better prints.

For best results and optimal print quality, we highly recommend that you re-level your build plate after changing to a new nozzle. Note that a PrimaCreator nozzle might be compatible with your printer, but the distance between nozzle and build plate must be adjusted.

The process of making a PrimaCreator nozzle begins with a selected high-quality material. When the material reaches the factory, there is first an optical inspection made of the material that are going to be used for each batch of nozzles. Then it´s time to clamp the material, in other words, make it into a long rod. In our process this only is done once, in many other (cheaper) cases, this process must be repeated several times, often as many as 3-4 times and yet you don´t get the same results.

After this process, the material goes through an ultrasonic cleaning bath and after that it is cleaned again and protected against surface oxidation.

The nozzle will now take shape with millimeter precision, the tolerance is less than ± 0.01 mm.

The process of removing sharp edges from the nozzles is a very important step as this makes up a big part of the result. If there is to much sharp edges left on the nozzle it will make the nozzle more prone to clog. So it´s essential that the nozzle is very smooth and clean before it is used. In every batch a few nozzles are selected and cut in half to make sure that every specification is met, and that the surface is in perfect condition.

The nozzles are then checked for one last time and packed individually in a protective box – ready to be shipped to you.

The series of nozzles from PrimaCreator is the perfect choice for people who only wants the best and at a great value!

|

|---|

PrimaCreator Raise3D Pro2 Nickel Plated Copper Nozzle 0-6 mm - 1 pcs

PrimaCreator Raise3D Pro2 Nickel Plated Copper Nozzle 0,6 mm - 1 pcs

Fits to: Raise3D Pro2, Pro2 Plus and E2

The premium nozzles from PrimaCreator are a series of replacement nozzles that can make more difference for the result than you may think. To have a high-quality nozzle is like having a sharp pencil, you need it to get a great print.

All nozzles from PrimaCreator are made from the best high-quality brass, copper or steel (depending on type) and are completed in a state of the art factory. All nozzles are manufactured with a tolerance of less than ± 0.01 mm. This means that your filament will have a very smooth and clear surface while extruding which, of course, results in better prints.

For best results and optimal print quality, we highly recommend that you re-level your build plate after changing to a new nozzle. Note that a PrimaCreator nozzle might be compatible with your printer, but the distance between nozzle and build plate must be adjusted.

The process of making a PrimaCreator nozzle begins with a selected high-quality material. When the material reaches the factory, there is first an optical inspection made of the material that are going to be used for each batch of nozzles. Then it´s time to clamp the material, in other words, make it into a long rod. In our process this only is done once, in many other (cheaper) cases, this process must be repeated several times, often as many as 3-4 times and yet you don´t get the same results.

After this process, the material goes through an ultrasonic cleaning bath and after that it is cleaned again and protected against surface oxidation.

The nozzle will now take shape with millimeter precision, the tolerance is less than ± 0.01 mm.

The process of removing sharp edges from the nozzles is a very important step as this makes up a big part of the result. If there is to much sharp edges left on the nozzle it will make the nozzle more prone to clog. So it´s essential that the nozzle is very smooth and clean before it is used. In every batch a few nozzles are selected and cut in half to make sure that every specification is met, and that the surface is in perfect condition.

The nozzles are then checked for one last time and packed individually in a protective box – ready to be shipped to you.

The series of nozzles from PrimaCreator is the perfect choice for people who only wants the best and at a great value!

|

|---|

PrimaCreator Raise3D Pro2 Nickel Plated Copper Nozzle 0-4 mm - 1 pcs

Raise3D Pro2 Nickel Plated Copper Nozzle 0,4 mm - 1 pcs

Fits to: Raise3D Pro2, Pro2 Plus and E2

The premium nozzles from PrimaCreator are a series of replacement nozzles that can make more difference for the result than you may think. To have a high-quality nozzle is like having a sharp pencil, you need it to get a great print.

All nozzles from PrimaCreator are made from the best high-quality brass, copper or steel (depending on type) and are completed in a state of the art factory. All nozzles are manufactured with a tolerance of less than ± 0.01 mm. This means that your filament will have a very smooth and clear surface while extruding which, of course, results in better prints.

For best results and optimal print quality, we highly recommend that you re-level your build plate after changing to a new nozzle. Note that a PrimaCreator nozzle might be compatible with your printer, but the distance between nozzle and build plate must be adjusted.

The process of making a PrimaCreator nozzle begins with a selected high-quality material. When the material reaches the factory, there is first an optical inspection made of the material that are going to be used for each batch of nozzles. Then it´s time to clamp the material, in other words, make it into a long rod. In our process this only is done once, in many other (cheaper) cases, this process must be repeated several times, often as many as 3-4 times and yet you don´t get the same results.

After this process, the material goes through an ultrasonic cleaning bath and after that it is cleaned again and protected against surface oxidation.

The nozzle will now take shape with millimeter precision, the tolerance is less than ± 0.01 mm.

The process of removing sharp edges from the nozzles is a very important step as this makes up a big part of the result. If there is to much sharp edges left on the nozzle it will make the nozzle more prone to clog. So it´s essential that the nozzle is very smooth and clean before it is used. In every batch a few nozzles are selected and cut in half to make sure that every specification is met, and that the surface is in perfect condition.

The nozzles are then checked for one last time and packed individually in a protective box – ready to be shipped to you.

The series of nozzles from PrimaCreator is the perfect choice for people who only wants the best and at a great value!

|

|---|

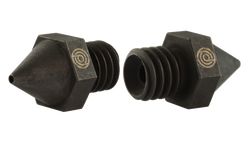

PrimaCreator Raise3D Pro2 Hardened Steel Nozzle 0-8 mm - 1 pcs

Raise3D Pro2 Hardened Steel Nozzle 0,8 mm - 1 pcs

Fits to: Raise3D Pro2, Pro2 Plus and E2

The premium nozzles from PrimaCreator are a series of replacement nozzles that can make more difference for the result than you may think. To have a high-quality nozzle is like having a sharp pencil, you need it to get a great print.

All nozzles from PrimaCreator are made from the best high-quality brass or steel (depending on type) and are completed in a state of the art factory. All nozzles are manufactured with a tolerance of less than ± 0.01 mm. This means that your filament will have a very smooth and clear surface while extruding which, of course, results in better prints.

For best results and optimal print quality, we highly recommend that you re-level your build plate after changing to a new nozzle. Note that a PrimaCreator nozzle might be compatible with your printer, but the distance between nozzle and build plate must be adjusted.

The process of making a PrimaCreator nozzle begins with a selected high-quality material. When the material reaches the factory, there is first an optical inspection made of the material that are going to be used for each batch of nozzles. Then it´s time to clamp the material, in other words, make it into a long rod. In our process this only is done once, in many other (cheaper) cases, this process must be repeated several times, often as many as 3-4 times and yet you don´t get the same results.

After this process, the material goes through an ultrasonic cleaning bath and after that it is cleaned again and protected against surface oxidation.

The nozzle will now take shape with millimeter precision, the tolerance is less than ± 0.01 mm.

The process of removing sharp edges from the nozzles is a very important step as this makes up a big part of the result. If there is to much sharp edges left on the nozzle it will make the nozzle more prone to clog. So it´s essential that the nozzle is very smooth and clean before it is used. In every batch a few nozzles are selected and cut in half to make sure that every specification is met, and that the surface is in perfect condition.

The nozzles are then checked for one last time and packed individually in a protective box – ready to be shipped to you.

The series of nozzles from PrimaCreator is the perfect choice for people who only wants the best and at a great value!

Marks/dots on Nozzle = Size

- 0 = 0.20mm

- 3 = 0.40mm

- 4 = 0.60mm

- 5 = 0.80mm

|

|---|

Artikel 51 - 100 von 395 gesamt.